Partial tasks

> Shielding of the experiment ATLAS

Shielding of the experiment ATLAS

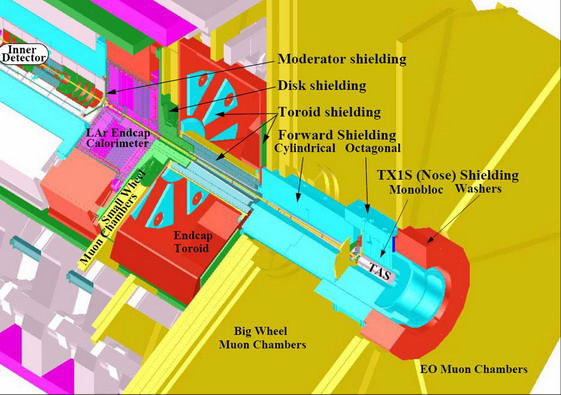

ATLAS detector contains several shieldings protecting its different subdetectors (see picture). IEAP CTU group participated in the R&D of the two ATLAS shielding - JM and JF. The effectiveness of different types of neutron shielding for the ATLAS forward region was studied by means of Monte-Carlo simulations and compared with the results of an experimental benchmark tests. Different types of shielding against neutrons and gamma rays, composed from different types of material, such as pure polyethylene, borated polyethylene, lithium-filled polyethylene, lead, iron and cast iron (ductile iron) were studied in details. The results from Monte-Carlo simulations were compared to the results obtained from the experiment on PS accelerator (4 GeV/c protons) and extended into the ATLAS energies. Based on the simulation results the final composition of the JF shielding was designed.

The czech group supervised the production of the JF shielding in the czech factories - ŠKODA Plzeň (now PILSEN STEEL, production of cast iron pieces), KOPOS Kolín (borated polyethylene bricks), TRANZA Chrudim (steel shielding) and Fest HF (final assembly). JF shielding was transported to CERN by Rádl company.

Effort of IEAP CTU physicists and the quality of the czech companies resulted in three other production agreements with CERN laboratory, JM shielding, JTT shielding as well as part of the ALICE detector shielding. The total amount of the production for CERN achieved 63.1 millions of the czech crowns.

Real performance of the ATLAS neutron shielding will be checked by network of monitors based on pixel detectors Medipix which is under installation in the ATLAS cavern and at different parts inside the ATLAS detector.

The czech group supervised the production of the JF shielding in the czech factories - ŠKODA Plzeň (now PILSEN STEEL, production of cast iron pieces), KOPOS Kolín (borated polyethylene bricks), TRANZA Chrudim (steel shielding) and Fest HF (final assembly). JF shielding was transported to CERN by Rádl company.

Effort of IEAP CTU physicists and the quality of the czech companies resulted in three other production agreements with CERN laboratory, JM shielding, JTT shielding as well as part of the ALICE detector shielding. The total amount of the production for CERN achieved 63.1 millions of the czech crowns.

Real performance of the ATLAS neutron shielding will be checked by network of monitors based on pixel detectors Medipix which is under installation in the ATLAS cavern and at different parts inside the ATLAS detector.

Responsible person

Articles in Impacted Journals

(4)

(4)

Text format

| Name | Author | Scientific journal |  Year Year

|

| Induced Radioactivity in the Forward Shielding and Semiconductor Tracker of the Atlas Detector | Bědajánek I.; Linhart V.; Štekl I.; Pospíšil S.; et al. | Radiation Protection Dosimetry (2005), Vol. 116, No. 1-4, pp. 16-18 | 2005 | |

| Monte-Carlo study of different concepts for the ATLAS experiment forward region shielding | Štekl I.; Bědajánek I.; Pospíšil S.; et al. | Nucl. Instr. Meth. Phys. Res. A493 (3), (2002) 199-207 | 2002 | |

| Monte-Carlo simulations of neutron shielding for the ATLAS forward region | Štekl I.; Pospíšil S.; et al. | Nucl.Instr. Meth. in Phys. Res. A 452 (2000) 458-469 | 2000 | |

| Experimental Tests of Neutron Shielding for the ATLAS Forward Region | Pospíšil S.; Štekl I.; Čermák P.; Jakůbek J.; Koníček J.; Linhart V.; et al. | Nucl. Instr. Meth. in Phys. Res. A 420 (1999) 249-258 | 1999 |

Search

Recent events

Seattle, USA

8-15 Nov 2014

Surrey, United Kingdom

Sep. 8, 2014

April 24, 2014

3 Apr 2014

Seoul, Korea

27 Oct - 2 Nov 2013

Paris

23-27 June 2013

29 Oct - 3 Nov 2012

Experimental physics

with polarized protons, neutrons and deuterons

Experimental physics

with polarized protons, neutrons and deuterons Progressive detection methods in atomic and particle physics education at middle and high school level

Progressive detection methods in atomic and particle physics education at middle and high school level NSS MIC IEEE Conference

NSS MIC IEEE Conference SEPnet, CERN@school Conference

SEPnet, CERN@school Conference Lovci záhad - natáčení ČT ve spolupráci s ÚTEF

Lovci záhad - natáčení ČT ve spolupráci s ÚTEF Advanced detection methods in atomic and subatomic physics education.

Advanced detection methods in atomic and subatomic physics education. Listening to the universe by detection cosmic rays - visit of French and Czech students

Listening to the universe by detection cosmic rays - visit of French and Czech students NSS MIC IEEE Conference

NSS MIC IEEE Conference 15thIWORID

15thIWORID NSS MIC IEEE Conference

NSS MIC IEEE Conference